Blazing of gratings refers to an optimization of the grating groove profile such that certain desired diffraction orders display enhanced diffraction intensity. For reflection gratings this is often achieved with a sawtooth-like groove profile, where orders near the direction of specular (mirror-like) reflection from the groove facet are enhanced. Typically, utilization of higher diffraction orders is desired, since it leads to higher spectral resolving power in grating spectrographs. Blazing can therefore be used to direct more flux into higher diffraction orders.

Blazed reflection gratings traditionally were made with so-called ruling engines, scribing grooves in metal films using a diamond tip. For large gratings this is a very slow process, and the resulting groove profile is non-ideal and difficult to control due to wear and other problems. See here for more details.

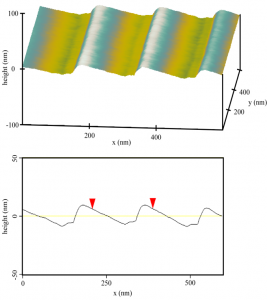

In the late 90’s we pioneered the combination of patterning using interference lithography, anisotropic etching of off-cut silicon substrates, and nub-removal to produce blazed soft x-ray reflection gratings with record diffraction efficiency in the so-called in-plane mount [1].

Space-based x-ray grating spectrographs need to cover large telescope apertures. When hundreds or thousands of gratings might be necessary it can make economic sense to fabricate a small number of grating “masters” and make many replicas from these masters in a fast and inexpensive fashion. Early replication methods (often epoxy-based) suffered from reduced diffraction efficiency due to imperfect groove profile replication. In addition, the so-called extreme off-plane mount offers distinct advantages over the in-plane mount [2]. In the early 2000’s we used the emerging technique of nanoimprint lithography to replicate blazed sawtooth reflection gratings from anisotropically etched silicon masters [3,4]. The metal-coated replicas exceeded 40% diffraction efficiency in blazed orders, very close to theoretical predictions [4,5].

Since the invention of soft x-ray/EUV critical-angle transmission (CAT) gratings in 2005 we have focused on the development of this new technology. Nevertheless, x-ray reflection gratings are still useful in many applications. We have fabricated anisotropically etched reflection gratings with sawtooth profiles for high-resolution soft x-ray and EUV spectroscopy after coating with multilayers [6,7] for applications such as resonant inelastic x-ray scattering. Currently we are fabricating a blazed variable-period x-ray reflection grating for the MaGIXS sounding rocket, scheduled for launch in early 2020 [8].

[1] A. E. Franke et al., “Super-smooth x-ray reflection grating fabrication”,

J. Vac. Sci. Technol. B 15, 2940 (1997).

[2] W. C. Cash, “X-ray optics. 2: A technique for high resolution spectroscopy“,

Appl. Opt. 30, 1749 (1991).

[3] C.-H. Chang et al., “Fabrication of sawtooth reflection gratings using nanoimprint lithography”,

J. Vac. Sci. Technol. B 21, 2755 (2003).

[4] C.-H. Chang et al., “High fidelity blazed grating replication using nanoimprint lithography”,

J. Vac. Sci. Technol. B 22, 3260 (2004).

[5] J. F. Seely et al., “Efficiency of a grazing incidence off-plane grating in the soft x-ray region”,

Appl. Opt. 45, 1680 (2006).

[6] M. P. Kowalski et al., “Near-normal incidence EUV efficiency of a flat crystalline anisotropically-etched blazed grating”,

Appl. Opt. 45, 1676 (2006).

[7] D. L. Voronov et al., “High efficiency 5000 lines/mm multilayer-coated blazed grating for extreme ultraviolet wavelengths”,

Opt. Lett. 35, 2615-2617 (2010).

[8] K. Kobayashi et al., “The Marshall grazing incidence x-ray spectrometer (MaGIXS)”,

Proc. SPIE 10699, 1069959 (2018).

Pdf versions of papers from our lab can be found here.